Tech Briefs

Savannah River National Laboratory

Solid Oxide Reduction for Treatment and Recovery of Key Elements from Used Nuclear Fuel and Rare Earth Ore Deposits

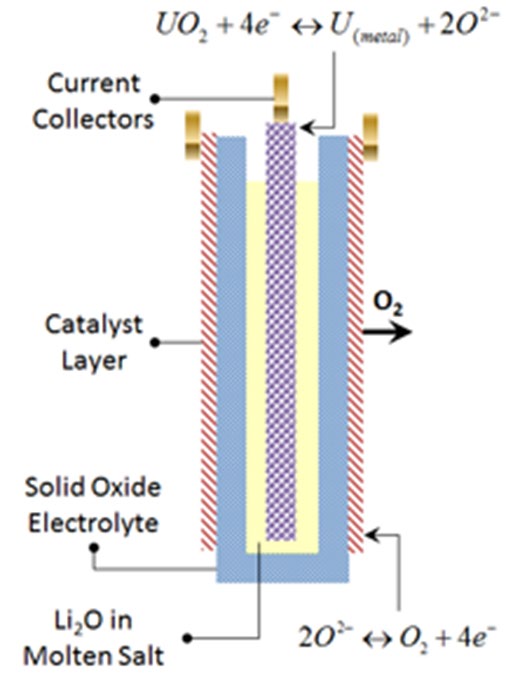

Researchers at the Savannah River National Laboratory (SRNL) have developed a process for potential use of the solid oxide membrane as the reaction vessel, while serving as the anode in an electrochemical cell.

Background

SRNL has developed a method for reducing metal oxides for nuclear and industrial applications that uses a solid oxide membrane to isolate the anode from molten salt electrolytes. The proprietary SRNL technique eliminates degradation of the electrode material by isolating it from the molten salt and increases process efficiency by through selective oxidation at the anode because only oxygen can be conducted through the solid oxide materials. This process leverages research on solid oxide electrolytes for fuel cells. This process can be used to reduce nuclear materials for pyroprocessing as well as in the industrial production of light metals such as titanium.

At a glance

- Metal reduction process

- with high efficiency

- Stable anode configuration Long anode lifetime

- Low electrode replacement costs

- Prototype system developed

- Patent applied for

How it works

The oxide material is reduced at the cathode and the oxygen from the metal oxide forms oxygen species such as Li2O in the molten salt. The Li2O transports the oxygen to the solid oxide membrane where it is conducted through the solid to the anode. At the anode, the oxide ions in the solid oxide membrane combine and are oxidized to oxygen gas. This process leaves the reduced metal as a product at the anode and the oxygen gas from the cathode can be released to the atmosphere.

Stage of development

This technology is conceptual with current development of a prototype.

Possible fields of interest include used fuel reprocessing and recovery of rare-earth elements. It would have potential commercial uses in processes for nuclear fuel reprocessing, the refining of rare earth metals, and general refining of steel and other industrial metals.

A patent has been filed with the U.S. Patent and Trademark Office.

Partnering opportunities

SRNL invites interested companies with proven capabilities in this area of expertise to develop commercial applications for this process or product under a cooperative research and development agreement or licensing agreement. Interested companies will be requested to submit a business plan setting forth company qualifications, strategies, activities, and milestones for commercializing this invention. Qualifications should include past experience at bringing similar products to market, reasonable schedule for product launch, sufficient manufacturing capacity, established distribution networks, and evidence of sufficient financial resources for product development and launch.

Download Tech Brief

Contact Information

Savannah River National Laboratory

E-mail: partnerships@srnl.doe.gov