Tech Briefs

Savannah River National Laboratory

Environmental Biocatalyst – BioTiger™

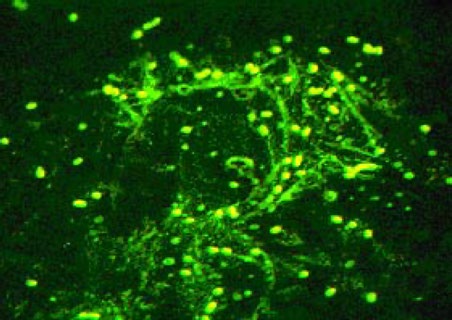

A novel, surfactant-producing microbial consortia that remediates polycyclic aromatic hydrocarbons (PAHs) and heavy metals has been isolated from a century-old oil refinery in Poland. The BioTiger™ consortium is highly resilient and effective having been isolated from a location with over a century of exposure to extreme environmental conditions, petroleum hydrocarbons, heavy metals, and associated solvents. This environmental biocatalyst has properties and capabilities not demonstrated elsewhere. Potentially, the biosurfactant could be used as a cleaning or degreasing agent.

The bacteria strains produce biosurfactants Under in situ and ex situ remediation conditions. The biosurfactant provides increased solubility of PAHs and access of the bacteria to the PAHs, thereby increasing the efficiency of the bioremediation. By use of microbes to accelerate remediation, treatment time for petroleum contaminated soil can be reduced to as little as 90 days. Cost savings can be achieved not only by the reduction in time of remediation but also by the ability to dispose of waste as not being mixed.

BioTiger™ removes complex PAHs and metals

At a glance

- Destroys 4-ring and higher PAHs

- Recovers heavy metals

- Greatly reduces treatment time

- Avoids disposal as mixed waste

- U. S. patent 7,472,747 B1

- U. S. patent 7,473,546 B2

BioTiger™ microbe surfactant reclaims land polluted by petroleum and heavy metals

PAHs are widespread pollutants particularly found in association with oil refineries, certain refined petroleum products, petroleum storage locations, and petroleum spill sites.

Other locations with contamination of sediments and water by PAHs and metals include energy production facilities, wood treatment locations, harbors, brownfields, municipal and commercial waste disposal sites, and military installations including coastal harbor areas. High levels of PAHs are associated with mutagenic and carcinogenic effects in humans and pose a high risk for migration to, and pollution of, soil and groundwater.

In situ bioremediation of wastes at landfills with or without the subsequent mining of the non-biogradable material for disposal elsewhere would allow the re-use of significant portions of landfill space.

Removes complex PAHs

Low molecular weight, 2- to 3-ringed PAHs such as naphthalene, phenanthrene, and fluoranthene along with PAH degradation intermediates are removed by this technology. Also degraded and removed, are 4-ring and higher molecular weight PAHs including pyrene and fluoranthene. Typically, the 4-ring and higher PAHs are much more persistent in the environment and resistant to degradation compared to low molecular weight PAHs. The removal of 4-ring and higher PAHs by this technology is significant.

Removes metals

This biocatalyst has surfactant properties produced by biosufactant monomers useful in the removal of metals from contaminated soil and substrates. The biosurfactant monomers are produced in sufficient quantity that the monomers aggregate into polar head groups which bind with metal ions in the soil. The micelles, containing the metal ions, can be removed by aqueous suspensions or flushing, thereby lowering the metal ion content of the substrate. The resulting removed metals, contained within the biosurfactant micelles, are then more easily separated and concentrated for efficient disposal or storage. The metals could be recovered for recycling.

Partnering Opportunities

SRNL invites interested companies with proven capabilities in this area of expertise to develop commercial applications for this process under a cooperative research and development agreement or licensing agreement. Interested companies will be requested to submit a business plan setting forth company qualifications, strategies, activities, and milestones for commercializing this invention. Qualifications should include past experience in the commercial uses of similar processes, reasonable schedule for commercial process launch, an established customer base, and evidence of sufficient financial resources for product development and launch.

Download Tech Brief

Contact Information

Savannah River National Laboratory

E-mail: partnerships@srnl.doe.gov