Unwrapping the World of Packaging: SRNL and SRNS Team Up to Lead Hazardous Materials Packaging Course

Many of the projects at Savannah River Site (SRS) require specialized packaging to transport and store radioactive and other hazardous materials. Regardless of whether a team is working on a defense, nonproliferation, or material storage project, Savannah River National Laboratory’s (SRNL) Packaging Technology Group is likely to have a hand in ensuring the material is properly contained.

The work and science behind packaging is not common knowledge to everyone at SRS, even to those who work directly with hazardous materials. Packaging group managers from SRNL, Savannah River Nuclear Solutions (SRNS), and Savannah River Plutonium Processing Facility (SRPPF) wanted a way to ensure new hires and engineers got first-hand experience with the site’s utilized packages.

Through the recently launched SRNL Nuclear Nonproliferation Program Group’s Knowledge Transfer program, SRNL’s Mobile Plutonium Facility (MPF) Packaging Team came together to offer a site-wide course focusing on the design and use of Type B Radioactive Material Packages, as well as some Type A(F) Packages.

Packages are categorized into groups based on the allowable activity of radioactive containment, for example, Type B packages contain high levels of radioactivity such as spent fuel from nuclear power plants.

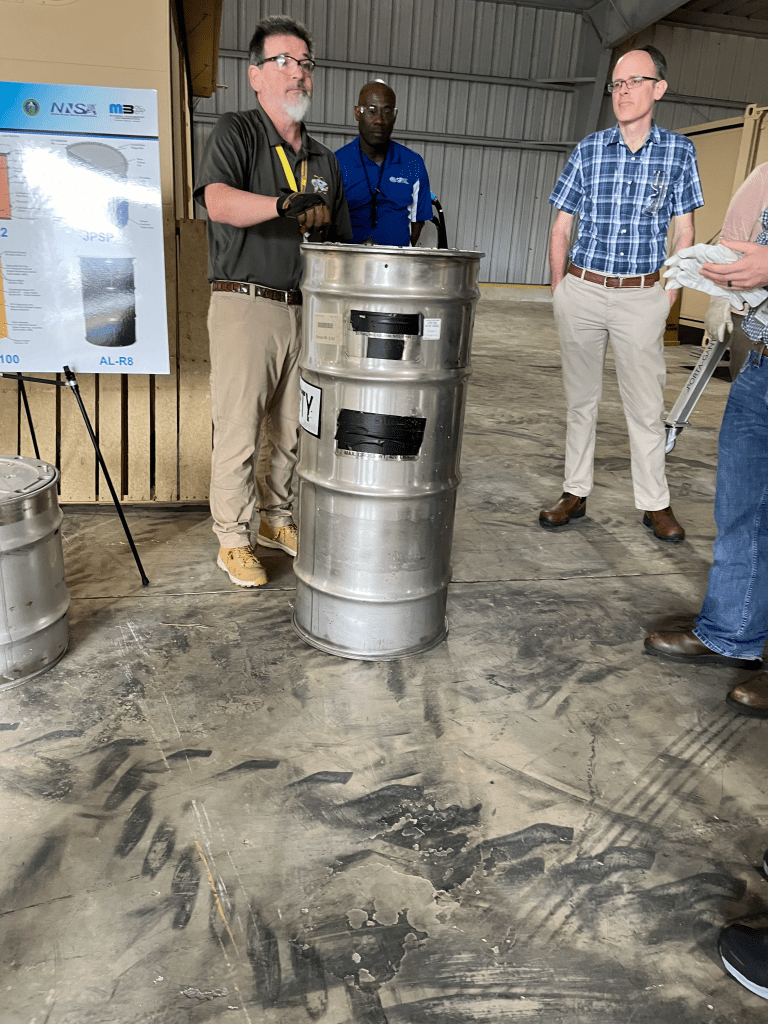

Rich Koenig (left) and Wayne (Doug) Holiday (middle) brief course attendees on a drum-style Type B Packaging. (SRNL)

SRNL Senior Engineer and Team Lead for Packaging Sustainment Juan Licea-Yañez; Rich Koenig, a program manager for nonproliferation at SRNS; and Wayne (Doug) Holiday, leak test group lead at SRNL, are members of a small, select group of staff at SRS who are authorized users of Department of Energy (DOE) Complex non-cask Type B containers. They also serve as the packaging subject matter experts for SRNL’s MPF and brought together their expertise to lead the two-day packaging course. Personnel from SRNL and SRNS joined to learn about the design and use of Type B packages.

“[Packaging] is a fairly niche world, but it’s something that touches, at least briefly, every major project that the lab does, or will do,” Licea-Yañez said. “A lot of people who work on these projects have never laid hands on or even physically seen a ‘packaging.’”

Licea-Yañez says that while many, like those who work as a design authority, may never have to operate a package, courses like this one are important to provide the information workers need to understand what they may be dealing with.

“I finally had the opportunity to physically see and get firsthand experience with packaging I have only read or wrote about in documents,” SRNL Packaging Technology Engineer Miranda Albert said after taking the course. “It is priceless to see the operation process in person and get a unique chance to see rigging, tool operation, and packaging components up close.”

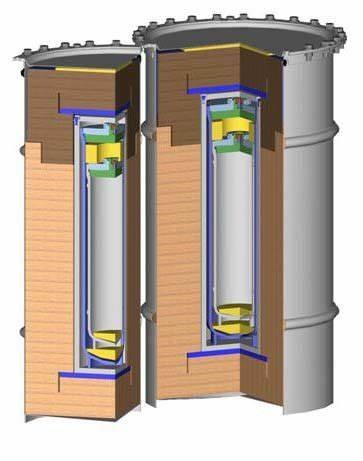

SRNL owns many of the packages that are used at SRS, including one of the more popular Type B packages, the 9975, which is used for storage in K-Area. The lab’s packages come in drum-style containers, and while many of the packages serve a similar purpose, the course was designed for participants to understand the features and nuances that are critical to the safety of each package’s function. Even the slightest modifications can significantly change the composition of the container’s capacity and role.

“A slight modification to the configuration of components inside of the 9977 containment vessel can essentially double the payload capacity of the package with no other necessary modifications,” Licea-Yañez said.

Illustration of one of the most popular Type B packages, the 9975. (Illustration from Safety Analysis Report for Packaging (SARP))

There are other courses at SRNL sponsored by the Department of Energy (DOE) through its Packaging University. These courses focus less on the specifics of individual packages and more on topics that include preparation for Safety Analysis Reports for Packaging (SARPs) or operations and leak testing.

The success of this first course has inspired Koenig to work toward turning it into a symposium in the future in conjunction with SRS Site Training. The initial course was made up of 15 participants from packaging and operations, but the team is looking to expand the course to transportation services, radiological control, and any others who are within the package world. Continuing to educate and train workers on packaging reinforces safety as the priority at SRS.