The Successful History of Safety Culture at SRNL

Savannah River Laboratory (SRL) was created in the early 1950s to support the scientific missions at the Savannah River Plant (SRP).

The lab was a semi-independent organization on SRP but was run by the DuPont company, which designed, built and operated the entire plant.

DuPont vigorously instilled a culture of worker safety before the first shovelful of dirt was tossed during construction.

Announcement from 1968 of the lab’s first DuPont Board of Director’s Safety Award (left) and related employee merchandise awards (right) (images: Savannah River Plant News).

Five nuclear reactors and the related chemical and engineering processes for producing nuclear materials for the nation’s defense created a highly radioactive work environment at several locations on site, including several research facilities at the lab.

For efficiency and consistency, both the larger plant and the lab were placed under the same safety organization. The plant assigned the lab a full-time safety engineer early on for leadership in this area.

Safety permeated all aspects of the lab, from the design and construction of the buildings to the daily activities within their walls.

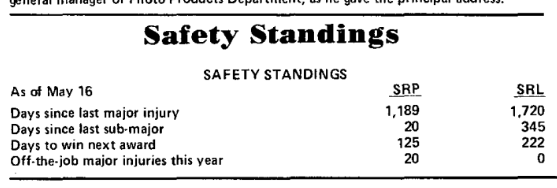

DuPont’s relentless emphasis on safety was never in the background. The plant newspaper, Savannah River Plant News, published safety articles, statistics and tips in every edition. The lab’s safety statistics were typically listed next to the plant-wide safety statistics.

As the decades progressed, SRL changed from Savannah River Technology Center to Savannah River National Laboratory (SRNL). Yet, the paramount nature of safety at the lab remained constant.

Safety culture was not confined to workers potentially exposed to radiation. It extended to all aspects and avenues of work at the lab, including simple office work. Furthermore, lab leadership stressed the safety of its workers and their families off the job.

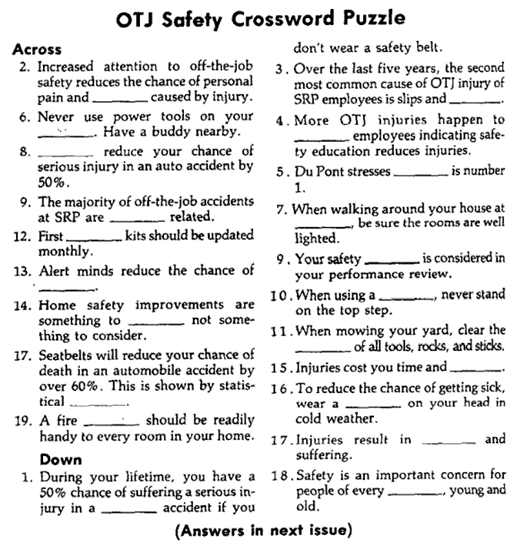

Safety crossword puzzle from Savannah River Plant News, January 30, 1986.

In the 20 years since the designation as a Department of Energy (DOE) national laboratory, SRNL has continued its dedication to safety culture.

The lab has an environmental, health, safety and quality department. Meetings at SRNL start with a timely safety-related discussions.

The SRNL newsletter references safety each week, and employees are required to review a deck of safety slides each month. The lab intranet site, The Nucleus, has a central safety page.

SRP and SRL safety statistics from Savannah River Plant News, May 20, 1976.

While leadership prioritizes safety at the lab, the employees continue the effort.

SRNL has its own employee-led safety organization, known as the Local Safety Improvement Team Continuously Honing and Maintaining Personnel Safety (LSIT Champs).

The organization has regular meetings open to the entire lab.

Since 2008, SRNL has participated in DOE’s Voluntary Protection Program (VPP), whose mission is “recognize and promote excellence in occupational, health and safety programs.”

SRNL entered Interim VPP STAR Status in June 2022 after the lab’s transition from Savannah River Nuclear Solutions (SRNS) to Battelle Savannah River Alliance (BSRA).

BSRA award plaque for the Department of Energy VPP STAR program (image: SRNL).

SRNL submitted a revised VPP application and a DOE-VPP assessment team will visit the lab this year to evaluate the program.

VPP STAR status is an important and prestigious external verification of SRNL’s safety management system and culture as a whole.

The pursuit of worker safety has paid off. The labs total reportable case (TRC) and days away, restricted or transferred (DART) rates are below the industry standard.

In 2022 the lab’s safety record was considered “best in class” compared to other DOE national laboratories.

SRNL engineers wearing proper personal protective equipment and reviewing safety items before starting a task (image: SRNL).