SRNL Pilot Experiment Enables Aluminum Spent Nuclear Fuel Disposition

As experts in corrosion evaluation and extended dry storage of spent nuclear fuel (SNF), scientists at Savannah River National Laboratory (SRNL) are poised to address a unique problem facing our nation. The U.S. possesses an inventory of spent nuclear fuel from nuclear research reactors that is susceptible to corrosion and requires safe processing and storage to avoid continued degradation. Current long-term storage options for research reactor fuel involve expensive monitoring and maintenance of the systems and components for storage to protect the SNF against degradation. Expected closures of aging processing and storage facilities will also reduce SNF storage capacity for additional SNF from future reactor discharges.

SRNL and the Idaho National Laboratory (INL) began collaborative research efforts to combat the challenges of aluminum-clad spent nuclear fuel (ASNF) in extended dry storage in 2018. Those efforts are now coming to fruition as SRNL embarks on a dry storage pilot experiment with the support of several collaborators, including INL, Oak Ridge National Laboratory, Holtec Government Services and Savannah River Nuclear Solutions.

The Commercial Power industry has an established strategy for long-term SNF dry storage with anticipated repository disposition. After fuel has been used in a reactor, it is removed and stored in water to safely cool. Once the appropriate temperature has been reached, the SNF is packed into a container, which is then dried, filled with inert gas to prevent corrosion and other degradation, sealed and moved to storage pads to await final disposition. This dry storage is designed to maintain the SNF in a retrievable condition to keep future options viable, such as repackaging or chemical processing.

Nuclear fuel is encapsulated in a cladding, an outer covering that contains the fuel and protects it from corrosion. Fuel can be clad in a variety of materials, commonly stainless steel or zirconium, but some of the research reactor fuel is clad in aluminum. Unlike stainless steel or zirconium, aluminum cladding corrodes underwater in the reactor or wet storage and a hydroxide layer develops. This hydroxide layer on ASNF poses challenges for storage in sealed canisters, as the radiation from the SNF can break it down over time, releasing hydrogen and potentially oxygen. A build-up of these two elements could increase pressure and create a flammable gas mixture within the storage container.

Irradiation cavity of the irradiator containing two stainless-steel “mini-canisters” loaded with aluminum samples under helium, designed to simulate the dry storage configuration for ASNF. Photos by Christopher Verst.

Unlike commercial SNF, ASNF has been centralized at Department of Energy (DOE) sites and handled in a few different ways:

- It may be kept underwater beyond its initial cooling period (wet storage).

- It may be dried and placed in a vented dry storage facility that allows gases to escape.

- It may undergo chemical processing to allow recovery of useful isotopes, followed by vitrification to transform the dissolved SNF into glass or another stable form.

The facilities currently used for processing of research reactor ASNF are slated to stop processing in the next decade. As a result, sealed dry storage similar to the commercial SNF approach is now an attractive alternative that provides stable, low-maintenance, long-term storage provided the performance of the ASNF in sealed storage is well understood and can be done safely.

Through lab scale experiments conducted in pursuit of an alternative long-term disposition solution, SRNL and INL scientists have observed that the hydroxides on ASNF do in fact generate hydrogen, but not oxygen. These results indicate ASNF can be placed in sealed packages for safe storage like commercial fuels without generating a flammable mixture and that, with appropriate drying and loading, the canister pressure will remain within acceptable limits. If this direction is taken, new storage canisters will be utilized for both storage and direct placement into a transportation package to be moved to future storage facilities or a repository.

After several years of laboratory testing, the findings will be applied to a real-world test through a pilot experiment. SRNL scientists will utilize modified, full-scale storage canisters that will allow instruments to collect data inside the canister, which is not possible in standard sealed canisters that are welded closed.

These canisters will be loaded with actual ASNF from the High Flux Isotope Reactor, dried and monitored for at least one year to confirm whether the observed canister temperatures and gas generation match expectations from model simulations.

The pilot canisters will be staged on the Savannah River Site with a goal of data collection beginning in 2028. If the laboratory results are replicated in the pilot experiment, a new standard for long-term sealed dry storage of ASNF will be established and a basis will exist to enable a decision to proceed with this drying approach for disposition of remaining ASNF across the DOE Complex.

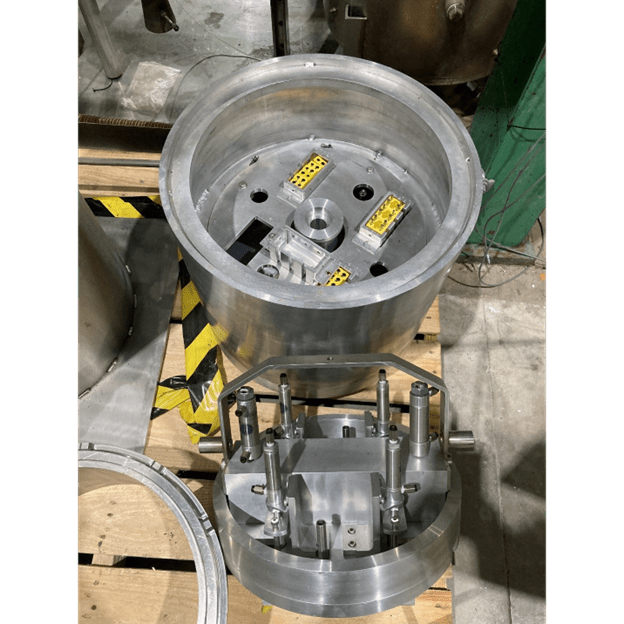

Prototypes for an instrumented canister lid (top) and remote-connection interface (bottom) for monitoring temperatures and gas composition in a full-scale canister loaded with actual ASNF, as planned for the ASNF Dry Storage Pilot. Photo by Anna d’Entremont.