SRNL Develops Technologies for the Emerging Advanced & Small Modular Reactor Fuel Cycle

“Our experience is with development and application of modular approaches to nuclear materials processing. The ability to provide right-sized process capabilities is very applicable to the emerging fuel cycles associated with advanced small modular reactors.” – Bill Bates

SMR fuel ecosystem (Susanna King, SRNL)

The nuclear energy landscape is changing. Public attitudes toward nuclear energy have shifted, with a majority of Americans (57 percent) indicating they favor nuclear power plants for electricity generation – an increase of 14 percent since 2020. The look of nuclear power for electricity generation is similarly changing, as conversation in the industry increasingly centers more on the advantages of advanced small modular reactors to deliver safer and more secure nuclear energy, and less on the traditional large nuclear power plants. While those conversations are largely focused on how and where advanced small modular reactors can be used, Savannah River National Laboratory is leading conversations about solving fuel cycle challenges with focus on the “backend” or waste disposition for these small reactors.

As a multidisciplined, federally funded research and development center, Savannah River National Laboratory continuously seeks to understand technology gaps that emerge as new processes and industries develop. SRNL leverages its decades of applied science and technology expertise in spent nuclear fuel and waste disposition technologies to address these emerging gaps.

According to the Department of Energy, advanced small modular reactors are a key part of the Department’s goal to develop safe, clean and affordable nuclear power options ranging in size from tens of megawatts up to hundreds of megawatts, offering many advantages over larger nuclear plants including smaller physical footprints, lower capital investment, siting in locations not possible with larger plants, and provisions for incremental power additions.

As the U.S. moves to keep up with international competitors, SRNL is leading discussions to keep the nation from falling behind in fuel cycle and demobilization efforts surrounding small modular reactors.

Conversations about small modular reactor deployment need to include discussion about the fuel cycle and backend

“Our experience is with development and application of modular approaches to nuclear materials processing. The ability to provide right-sized process capabilities is very applicable to the emerging fuel cycles associated with advanced small modular reactors,” said Bill Bates, SRNL’s deputy associate laboratory director, Environmental and Legacy Management. Bates is quick to point out that discussions about advanced small modular reactors can’t stop with the reactor deployment; rather he says, those conversations need to include discussion about the fuel cycle.

“It’s more than just the new reactor, it’s about the fuel, it’s about how you deal with the reactor itself when you’re done and it’s about how you deal with the spent nuclear fuel. SRNL has experience in all of that,” said Bates.

There are challenges that come with the deployment (and demobilization) of an advanced small modular reactor (or microreactor) to a battlefield or to a location impacted by a natural disaster like a hurricane or earthquake. “Here, we’re talking about having to move spent nuclear fuel and highly irradiated material, and very likely the reactor itself,” said Bates. It is those backend process challenges that Bates believes are only starting to get attention, and for which SRNL is well-positioned and uniquely qualified to address.

“You can preserve the spent fuel to reuse it, in which case it would be packaged and kept intact for potential future use or isotope recovery, or you can stabilize it intact or process it into a waste form, and then package it for storage as a high-level waste,” said Bates.

SRNL’s capabilities in highly regulated modular system deployments allow the laboratory to serve as trusted advisors and science and technology experts in support of the fuel cycle and backend aspects for these reactors.

Bates points to five specific examples of SRNL’s relevant efforts in advanced small modular reactor fuel cycle technologies.

- TriStructural Isotropic fuel processing.

- Reprocessing technologies.

- Fuel optimization.

- High-Assay Low-Enriched Uranium feedstock.

- Packaging and transportation technologies.

Multiple companies plan to use TRISO fuel in small modular reactors or microreactors.

“TRISO fuel uses graphite as its cladding and moderator and SRNL has several patents on a technology for removal of that graphite,” said Bates. “We’re working to optimize that technology to allow for modular processing for recovery of HALEU from fresh fuel scrap during fuel fabrication or for treatment of spent nuclear fuel.” SRNL was recently awarded a DOE Office of Technology Transitions project in which SRNL is partnering with the University of South Carolina.

“The removal of the graphite from the spent TRISO fuel enables either the reprocessing of the spent fuel or a reduction of the volume of high-level waste requiring packaging, storage, transport and disposal. This is possible because SRNL’s process technology removes more than 90 percent of the fuel volume. In the processing, some neutron poison material is added back in but the final overall volume reduction of material is about 60 percent.” Bates notes that the elimination of the graphite yields carbon dioxide, but the work the lab is doing with the University of South Carolina aims to capture the CO2 and convert it into a solid form allowing it to be disposed of as low level waste.

“Our solution is an elegant way to process spent TRISO fuel, compared to many other approaches that have numerous challenges including grinding, burning, and cutting of graphite,” he said.

Bates’ next example is work SRNL is doing in collaboration with Metatomic Inc., following the award of a Gateway for Accelerated Innovation in Nuclear project where the lab is working with Metatomic to scale up their technology to take spent civilian nuclear fuel (such as spent fuel from a traditional nuclear power plant), remove the cladding and make it all (the isotopes are not separated) into a salt that can be used as fuel in an a molten salt reactor, one of several types of advanced small modular reactors. SRNL’s work here is on the backend of the commercial nuclear fuel cycle, but it’s the front end for a molten salt reactor. SRNL has completed the initial experiments converting uranium dioxide to uranium chloride, but much more work is ahead.

A DOE Advanced Research Projects Agency – Energy project is Bates’ third example. In this collaboration with TerraPower, uranium from used nuclear fuel is separated by a chloride-based volatility process designed to reduce waste volumes by recovering the uranium. The chloride-based volatility process uses the principle of fractional distillation to recover different chloride salts at selectively different temperatures. The process can be applied to metallic- and oxide-based reactor fuels with a goal to also adapt it to salt-based reactor fuel.

SRNL’s work with HALEU fuel feedstock is Bates’ fourth example. Here SRNL performs – for DOE’s Office of Nuclear Energy – detailed radiochemical analysis of all the high-enriched uranium cleaned up from the Savannah River Site’s H-Canyon facility, to support an advanced reactor fuel fabricator’s specifications once blended down to high assay low enriched uranium (Low Enriched Uranium consisting of the clean, highly enriched uranium from the Savannah River Site’s H-Canyon, blended with low enriched uranium or natural uranium to between 5 and 19.75% U-235 enrichment).

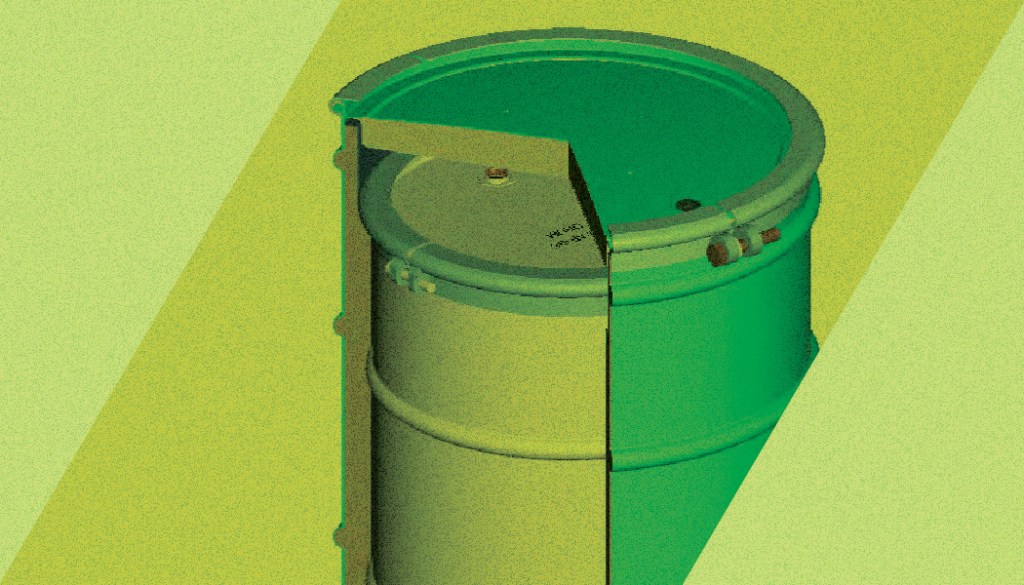

“Our packaging and transportation group is also working with Orano (under the same scope) on licensing a shipping package to be able to ship the HALEU in a liquid form to the fuel fabricator who will use this high-assay low enriched uranium to produce fresh reactor fuel,” Bates said. “The project demonstrates our expertise in packaging and analytical capabilities to support the initial feedstock for advanced small modular reactors of the near future,” he said.

Finally, SRNL’s expertise in packaging and transportation continues to drive innovation as demonstrated by SRNL’s development of a new shipping package and the expansion of SRNL’s existing packaging licenses to include fuel for modular reactors, such as TRISO, to be certified by the Nuclear Regulatory Commission for commercial use. This will enable the safe transport of unique unirradiated fuel from fabrication to future locations where the modular reactors will be used.

Bates notes SRNL also has other lines of work supporting the DOE Office of Nuclear Energy’s Nuclear Fuel Cycle (NE-4) and Spent Fuel & High-Level Waste Disposition (NE-8).

Seeking to solve the fuel cycle and “backend” challenges of small modular reactor deployment is another example of SRNL leveraging its 70 years of experience to provide solutions to tomorrow’s complex challenges.