Savannah River National Laboratory Advances Mk-18 Program Supporting Nuclear Nonproliferation

“Our equipment allows the removal of radiological material from the hot cells into packages for shipment to Oak Ridge National Laboratory.” – Alan Busby

Illustration of the Mark-18 cask arriving at the L-Basin Transfer Bay. (Kevin Hera, SRNL)

Savannah River National Laboratory has access to the only irradiated target assemblies containing a rare isotope ideal for use as a certified reference material used in nuclear forensics related applications. Called Mk-18 targets, they contain plutonium-244 — a very rare and extremely important material that can be used to support nuclear nonproliferation applications.

For decades the Savannah River Site has stored irradiated Mk-18 target assemblies, produced in nuclear reactors during the Cold War that were deactivated in the early 1990s. A National Nuclear Security Administration sponsored collaboration between SRNL and Oak Ridge National Laboratory in 2014 brought a renewed focus on the stored material as a valuable resource to benefit research and analysis in nuclear nonproliferation national defense missions. Specifically, the new NNSA Office of Environment, Safety and Health via the Nuclear Materials Integration Division is bringing the project to fruition.

Pu-244 is mostly found in outer space, which makes it hard to come by and sought after as a plutonium isotope. The U.S. supply is very low. The small quantity that remains came from Mk-18 targets that were processed to recover the rare isotope in the 1970s.

Last fall the SRNL team moved equipment into SRNL’s shielded cells, which are used for safe handling of irradiated nuclear material, for Phase I. It was a readiness phase to ensure the material could be properly removed from a pilot testing location, shipped to the lab, and moved into the shielded cells in accordance with SRNL’s high safety standards.

“SRNL will do the chemical separations from these targets. We’re not doing any isotopic purification; that will be done at Oak Ridge,” says Chris Armstrong, Separation Sciences and Engineering, Environmental and Legacy Management.

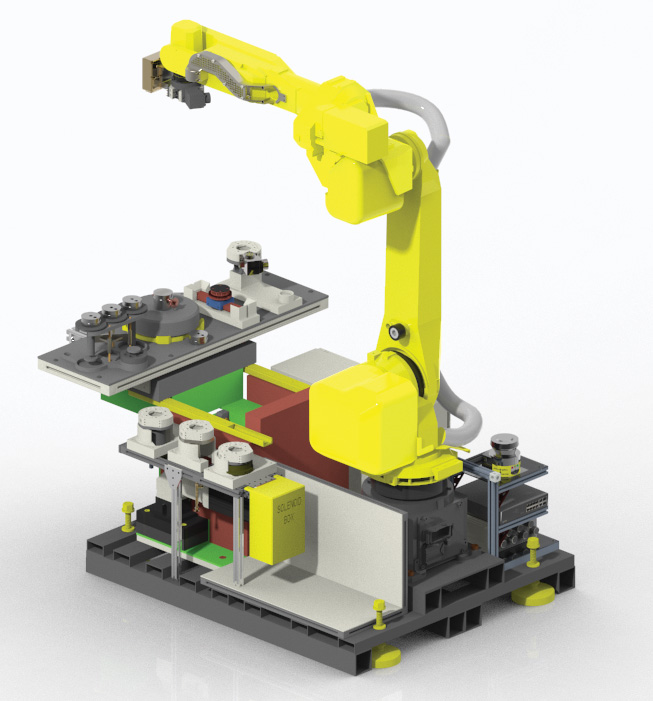

An SRNL-designed Bagless Transfer Packaging System went through final acceptance testing and was assembled outside SRNL’s shielded cells. Three cells will be used to extract material from the Mk-18 targets. The BTPS is one part of the overall system that will package americium and curium material byproducts for shipping to ORNL. Central to the BTPS is an automated induction brazing system, a process that joins metals together using induction heating, that ensures a clean seal.

“Our equipment allows the removal of radiological material from the hot cells into packages for shipment to Oak Ridge National Laboratory,” says Alan Busby, Advanced Engineering, Weapons Production Technology at SRNL.

Digital model of the Robot Packaging Skid (Kevin Hera, SRNL)

With this system, material can be taken out of a glove box or a hot cell and inserted into a can so it can be transferred safely without any external radiological contamination from inside the box or shielded cells. Ongoing cold runs ensure the system operates as intended before a hot start with the Mk-18 radiological material.

With the BTPS system, material is placed in the can and a plug, with a hollow center, is pushed into place and brazed in the desired position. The can is then cut in the center of the plug, creating a container that has never been in the hot contaminated environment to safely transfer the material for further packaging.

“Essentially, this process enables a can to be partially inserted into a hot, contaminated environment, with seals all around it. So, just the tip of the can is exposed to that environment,” says Busby.

Illustration showing the Robot Packaging Skid inserting a target into a can (Kevin Hera, SRNL)

While this is a simplified description of a complex process, the bagless can or container of material goes into another special-forms container and then into the drum for shipment from SRNL to ORNL. Four drums at a time will be circulated between SRNL and ORNL for reuse.

Before the BTPS is used, the overall process starts with a unique cask or container, also designed at SRNL, initially containing simulant material — eventually radiological material — in a water-filled spent nuclear fuel storage basin at SRS. Then the cask is shipped to SRNL where it is moved by a crane to a cask receipt table, where the individual target is transferred from the cask into the shielded cells. The target material is cut, and chemical separations begin. Once hot startup with radiological material begins later this year, it is estimated that shipments to ORNL will occur about every eight weeks, depending on other radiological work being performed in SRNL’s shielded cells.

The Mk-18 program continues to be a prime example of SRNL’s ability to develop and deploy unique scientific solutions to challenging problems in processing and recovery of valuable nuclear materials.