“By enabling the development of these unique nanotechnologies, new businesses, products, and industries could be created.” – Simona Murph

Simona Murph (right) and Michael Brown (left) monitoring controlled release of hydrogen isotopes from magnetic-hydride nanomaterials. (SRNS staff photo)

Simona Murph, SRNL’s 2023 Inventor of the Year, is widely recognized for her research in nanoscience and nanotechnology. She holds 20 patents and patent applications including her most recent one for nano-additive manufacturing, the science that enables scientists to create, assemble and print nanoscale materials.

Nanotechnology enables innovations across every sector of science and industry, including plasmonics electronics, catalysis, sensing, environmental remediation and biomedicine. Nanomaterials have the ability to advance clean energy technologies and industrial decarbonization processes through process intensification in manufacturing processes.

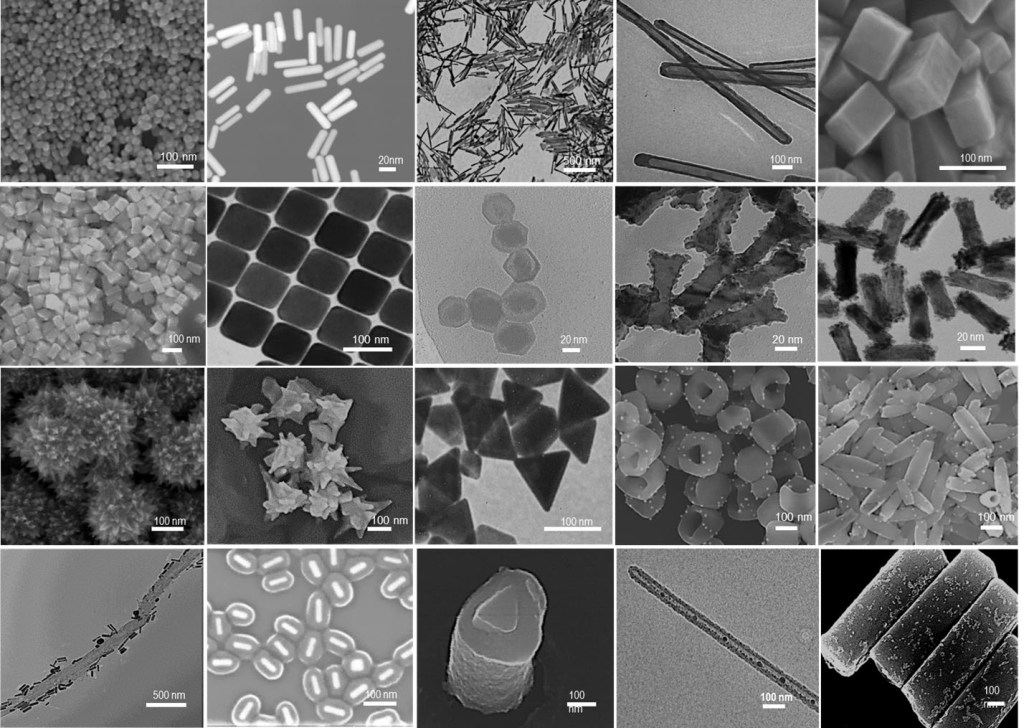

The research into nano-additive manufacturing also helps support SRNL’s missions through reduced use of energy and materials, efficient use of resources, and enhanced performance and function. The promise of nanomaterials as components of new technologies is due to their unique properties that arise at the small length scales of 1-100 nm. As material size decreases into the nano size regime, novel properties arise that are different from their molecular and bulk counterparts. Due to the size and shape effects in this regime, a nanoparticle’s morphology has a profound effect on its properties.

“We developed nano-additive manufacturing, a state-of-the-art nano-scale material production technology, that can, for a fraction of the cost of current methods, rapidly and continuously form high quality products with tunable dimensions, geometries and compositions,” said Murph. “An added benefit of this technology is that it generates nanomaterials with high product yield. Nanomaterials can be subsequently printed in organized architectures through defined control of the boundary conditions.”

Her research proves that shape-selective hybrid nano-antennas (like gold-iron oxide), an inexpensive and abundant material with magnetic functionalities, can photothermally heat aqueous solutions as efficiently as pure gold nanoparticles to transduce light into heat and significantly increase catalytic reaction rates. Remote separation and methodical manipulation of ‘payloads’ in the form of hydrogen isotopes has been successfully demonstrated using hydride-magnetic storage nanomaterials. These innovations expand the DOE’s energy security, fusion, and defense missions. Bio-medical applications of the technology are also being explored for chemotherapy drug delivery, nano-thermometer probes, tracking drugs inside the body and magnetic resonance imaging platforms.

Some of the nanomaterials examined at SRNL, as seen through a microscope. (Simona Murph, SRNL)

Her next goal is to find ways to incorporate nanomaterials into devices on a commercial scale and transfer of nano-additive manufacturing technology to the marketplace. “By enabling the development of these unique nanotechnologies, new businesses, products, and industries could be created, promoting the economy, and creating jobs,” said Murph. “Patenting our work increases company valuation and portfolio-attracting investors, increasing our credibility and reputation in the scientific field and in various industries.”

In addition to being named Inventor of the Year, Murph is a Brimacombe Medal winner and the first SRNL employee to be appointed to serve at the national level as a committee member of the DOE Office of Science, Fusion Energy Sciences Advisory Committee. She has mentored and supported 54 collegiate students, postdoctoral researchers and visiting faculty members at SRNL.

Benefits of nano-additive manufacturing

- High throughput

- Fast physico-chemical processes

- Flexibility in tailoring/creation of complex compositions, functionalities, and structures

- High quality products with higher yield

- Reduced chemical consumption and waste

- Online quality control analytical tools

- Continuous printing and patterning on/in 2D and/or 3D platforms

- Applicable for syntheses that involve challenging reactions