Applied Materials Science for Waste Immobilization

Applied Materials Science for Waste Immobilization

Applied Sciences

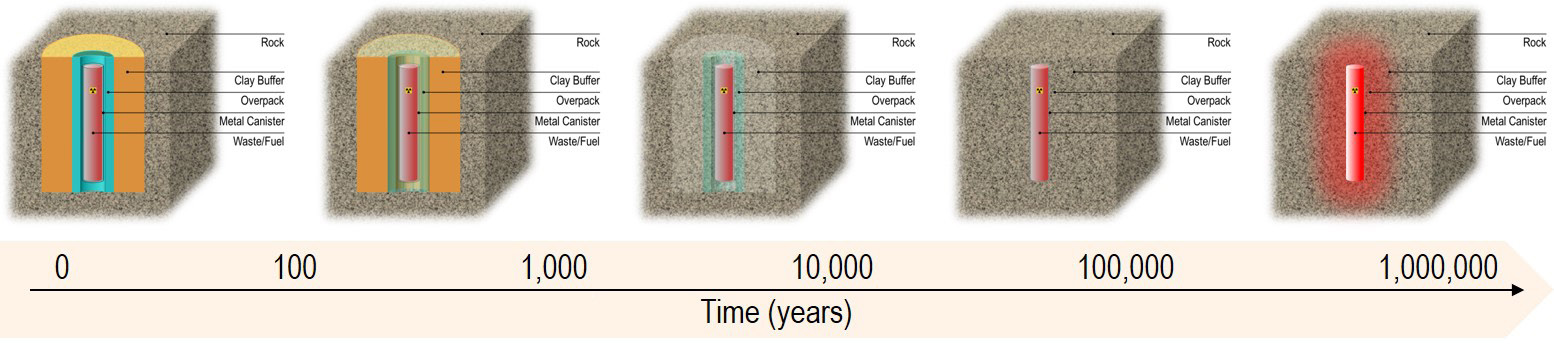

Savannah River National Lab (SRNL) continues to develop glass and ceramic materials to stabilize nuclear waste. These materials chemically bind the radioactive and hazardous components into a solid, durable material that will withstand degradation for thousands of years.

The choice between glass, ceramic, or glass-ceramic materials is dependent on the application and often is a compromise between factors such as cost, performance and suitability. Research into glass and ceramic materials at SRNL is carried out to help reduce the environmental and economic impact associated with treating radioactive wastes.

Performance Modeling

Fundamental to the principle and acceptance of a waste form is an ability to confidently predict a material’s performance well into the future. Equally necessary is the ability to process waste forms with a high level of reliability.

Attaining success in real systems requires robust modeling and system validation. Glass scientists and engineers develop models and carry out the necessary research and development needed to support this substantial undertaking.

Designing for the Future

SRNL is helping to accelerate the pace of research using big data techniques. For example, the Accelerated Leaching and Testing of GLASS (ALTGLAS) database, which is developed, maintained, and distributed by SRNL, provides researchers access to chemical durability data for thousands of glass compositions. This collection of data enables scientists to use informatics to analyze experimental results and to better understand glass corrosion science.

Conceptual representation of the barriers to radionuclide release and the long-term function of the waste form.

SRNL Fast Facts

- National Laboratory for DOE Office of Environmental Management

- Located at DOE’s Savannah River Site near Aiken, SC

- Operated by Battelle Savannah River Alliance, LLC

- Sectors served include Global Security, Science and Technology, and Environmental and Legacy Management

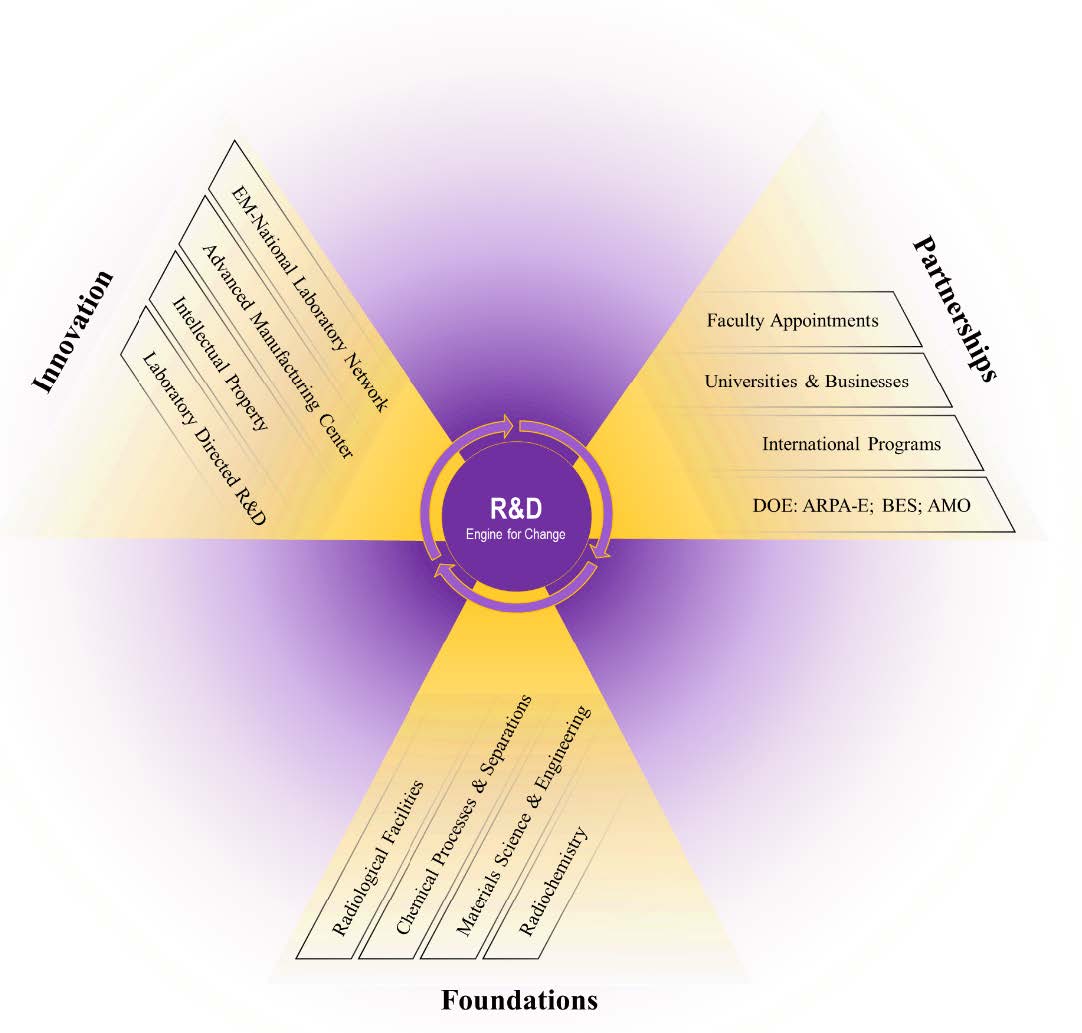

Research and Development – Engine for Change

SRNL applies foundational science and technical expertise developed over decades to grow partnerships and guide continued innovation in the following functional areas:

- Accelerating remediation, minimizing waste and reducing risk

- Enabling next-generation nuclear materials processing and disposition

- Engineering new materials and their applications with data-driven modeling and simulation

- Nuclear materials process design, development and demonstration

- Waste form development, qualification and disposition

- Scaled testing and demonstration

Novel Materials for Waste Storage and Isolation

SRNL collaborates with university partners to develop new waste form solutions.

Visiting graduate student performs radio-logical synthesis.

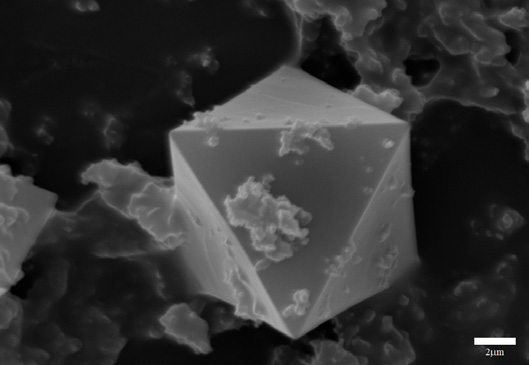

Single crystals of cubic Pu-MOF (Pu6C72H60O36F12).

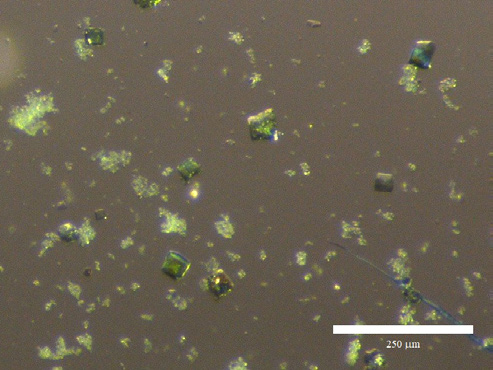

Faceted single crystals of NpMnF3 compounds prepared in SRNL’s radiological facilities.

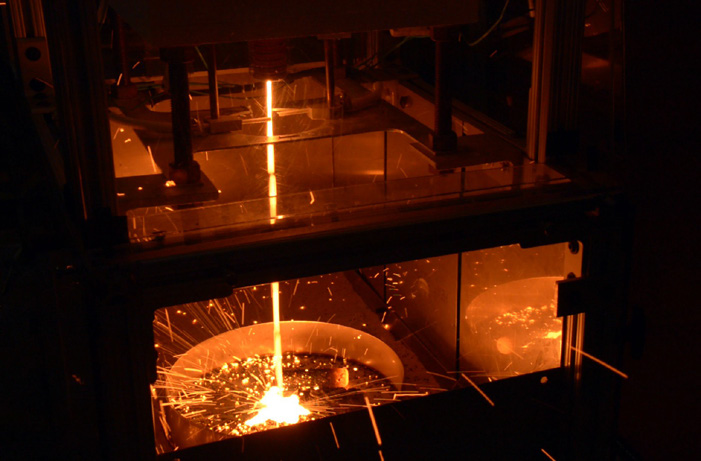

Advanced Melter Technology

SRNL is the premier DOE Environmental Management laboratory for scaled test bed design, assembly, and performance testing.

Ceramic being poured using one of SRNL’s research melters, capable of reaching temperatures in excess of 3000°F; proof-of-principle and first-ever sustained demonstration of a melt-cast ceramic waste form (non-radioactive) designed to stabilize a combined radioactive waste stream from reactor fuel reprocessing.